Marking is a crucial tool in the fight against counterfeiting. It allows for the distinction between genuine products and counterfeit ones, safeguarding the intellectual property rights of companies and ensuring consumer safety.

One of the most effective marking technologies is AstroMark Line's high-speed laser coding and marking systems. Our equipment delivers high-speed and high-precision creation of various types of markings, including barcodes, QR codes, serial numbers, and logos.

The advantages of high-speed laser coding and marking systems in the food industry cannot be underestimated. Such systems enable the application of clear and durable codes on various types of packaging, including plastic, glass, metal, and cardboard. They also provide high marking speed, which helps reduce production time and costs.

Mandatory labeling in the pharmaceutical industry is an integral part of drug manufacturing. It ensures the reliability, safety, and quality control of products.

High-speed laser coding and marking systems have become indispensable tools in this industry due to the marking’s high resistance to external factors such as moisture, light, temperature, and other storage and transportation conditions. This guarantees the integrity of the information on the packaging throughout the product's shelf life.

Mandatory marking in the machinery industry allows for the identification of each piece of equipment, tracking its origin, condition, and history, as well as preventing counterfeiting and counterfeit products.

Marking performed using high-speed laser systems is highly resistant to wear and tear, ensuring durability and readability even under challenging operating conditions.

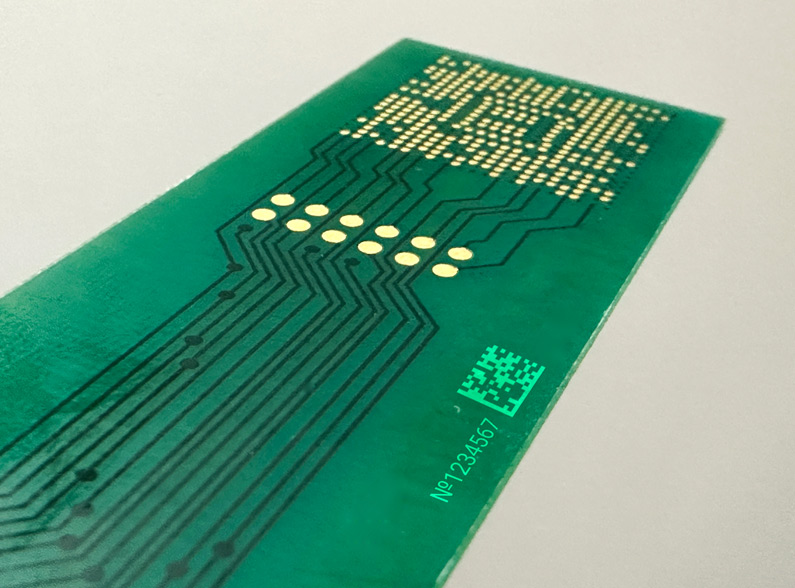

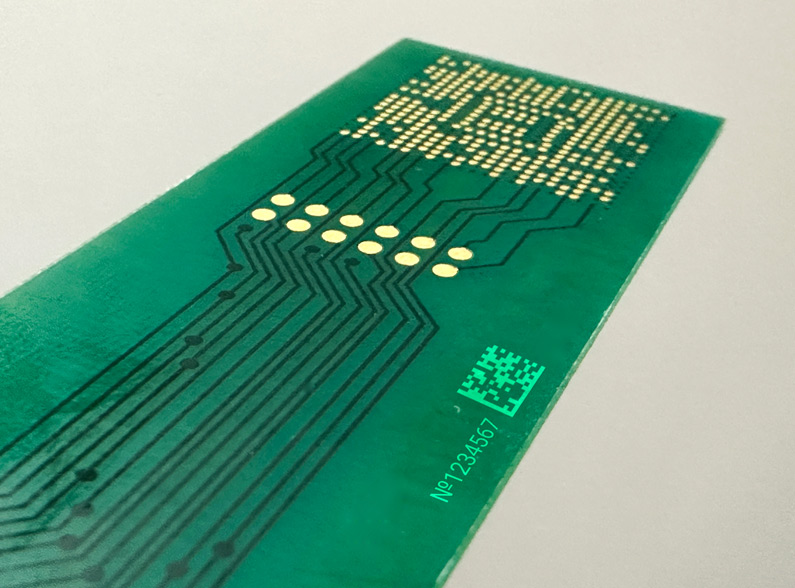

The use of super-fast laser coding and marking systems will undoubtedly bring numerous advantages to the process of marking electronic components.

By creating micro-fragments on the surface of the components, laser systems ensure the durability of the marking against external factors, such as corrosion or wear and tear.

Super-fast laser systems enable swift and precise marking on the surface of jewelry items, increasing the productivity and efficiency of the process.

Laser systems ensure precise and durable application of even the smallest codes (from 0.7x0.7 mm), serial numbers, logos, or any other information on jewelry items.